Intel Prepares 2000W class radiator for future chips

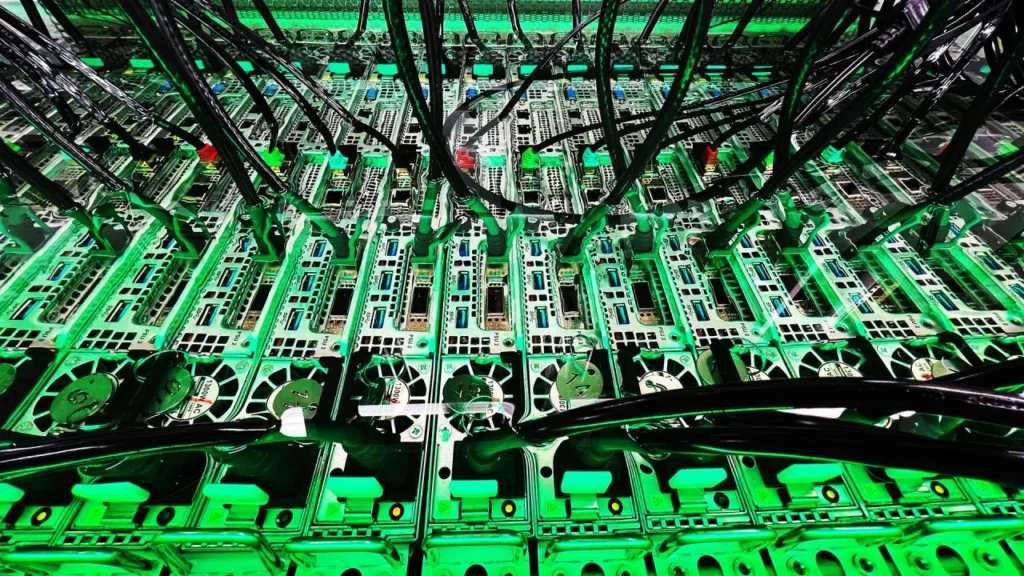

In the realm of PC hardware cooling, the options predominantly revolve around air or water cooling systems. However, with an ever-growing number of transistors on chips, Intel began investing early in the design of next-generation immersive liquid cooling solutions to better manage heat, conserve energy, lower costs, and reduce carbon emissions. They plan to launch the industry’s first open intellectual property immersive liquid cooling solution and public design, fostering the widespread adoption of immersive liquid cooling without necessitating substantial financial investment in custom solutions.

According to TomsHardware, Intel is not solely focused on immersive liquid cooling. Their developers are exploring innovative solutions to elevate the cooling capabilities of next-generation chips to a staggering 2000W level. Presently, Intel is seeking “new materials and structures,” collaborating closely with other inventive cooling technology companies to offer superior cooling techniques and develop “science fiction-like” thermal solutions.

Image credit: Intel

One of Intel’s novel thermal solutions is based on 3D isothermal plates, which distribute boiling capabilities within a sealed flat metal filled with liquid, utilizing minimal space and improved boiling-enhancing coatings. Research indicates that coral-like heat sink designs with grooved internal features exhibit the most potential in terms of external heat transfer coefficients for immersive liquid cooling. Intel envisions these ultra-low thermal resistance 3D isothermal plates integrated within coral-like immersive liquid coolers manufactured using additive manufacturing technology.

Another approach Intel is pursuing involves utilizing fluid ejector arrays to cool high-power devices, regulated by artificial intelligence. These ejectors can spray coolant directly onto the hotspots of the chips to dissipate heat. Intel’s thermal technology aims not only to enhance efficiency and conserve energy but also to enable chips to operate at lower temperatures, thereby boosting performance by 5% to 7% at the same power levels.