The industry has been rumored that Apple, as TSMC’s priority in terms of orders, has not only given priority to the production capacity of the 4nm process but also won the first batch of orders for the 3nm process. Apple is favored because of its huge resources and huge demand for self-developed chips. Its huge sales of iPhone, iPad, and Mac product lines will help TSMC maintain its profit level.

However, it was reported more than a month ago that not only Apple was the first to obtain TSMC’s 3nm process capacity, but Intel was also testing chip designs produced using TSMC N3 process. Although Intel has already determined that it will cooperate with TSMC, it has not disclosed any details. According to Wccftech, sources in the supply chain indicate that Intel has obtained orders for most of TSMC’s 3nm process nodes for the production of next-generation chips.

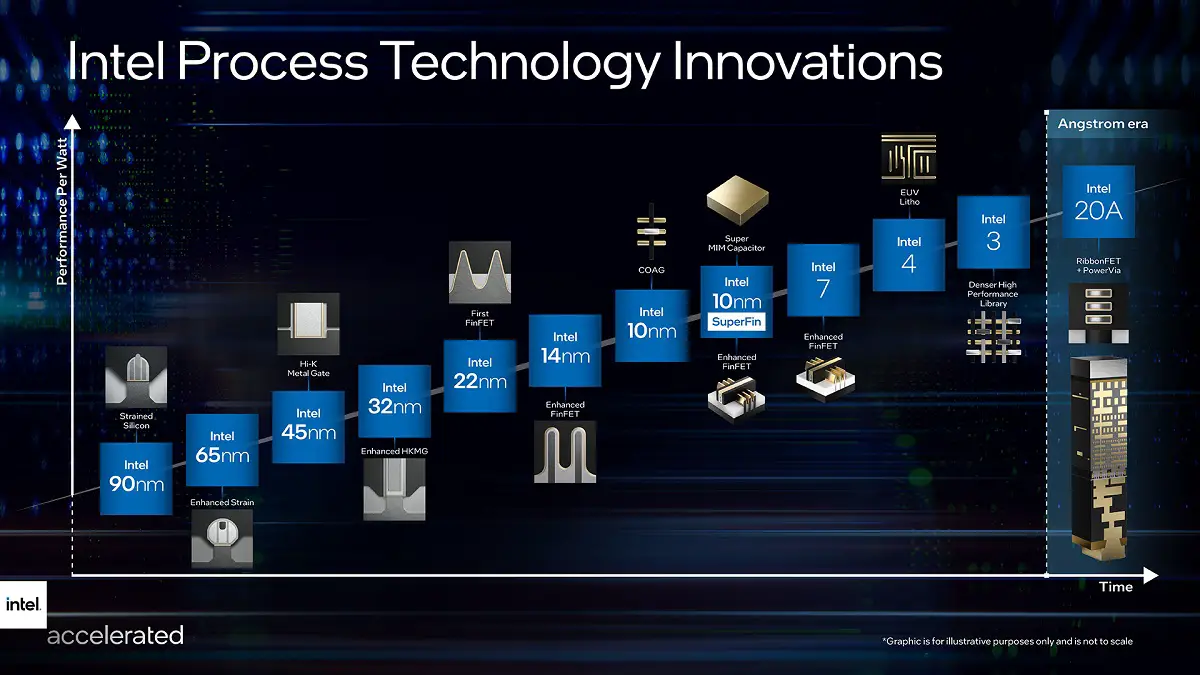

Image: Intel

TSMC’s Fab 18 wafer fab is expected to start production in the second quarter of 2022, with an initial capacity of 4,000 wafers per month, and after the mass production stage, it will reach 10,000 wafers per month. There have been rumors that some chips in Intel’s next-generation products will be produced using TSMC’s 3nm process to catch up with the process used by

AMD chips. There may be other factors for Intel to seize the capacity of TSMC. Because the capacity of this advanced process is limited, swallowing the capacity of TSMC’s 3nm process node will put pressure on other competitors.

It is understood that TSMC’s Fab 18 fab will use the 3nm process node to produce at least four products for Intel, three of which are for the server field, and the other is for the graphics field. However, it is temporarily unclear which products are. Since Intel can realize the interconnection of different process modules through EMIB/Forveros packaging technology, the modular design of the chip makes it possible to stack modules with different process nodes. There may be both Intel-produced modules and TSMC-made modules in the package.